SALIENT FEATURES

COMMON FEATURES

- PP (Polypropylene) / HDPE (High Density Poly Ethylene) Bags / Sacks available in coated as well as un-coated forms

- We will provide you the perfect packing to meet your exact requirement

- We are very careful on the sizes of the bags because that is very important for the looks of bags and also cost effectiveness. This is suggested by us for the particular applications

Available Variants In HDPE/PP Woven Bags or Sacks

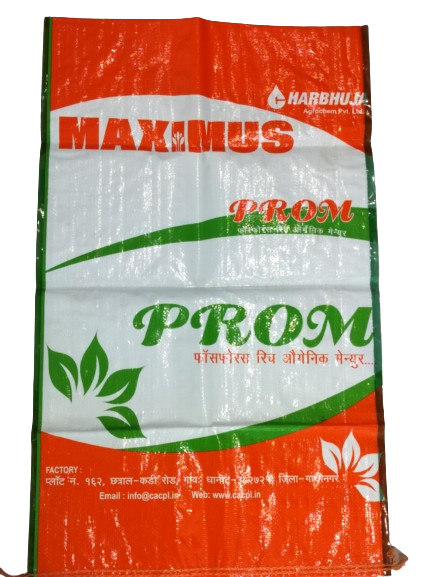

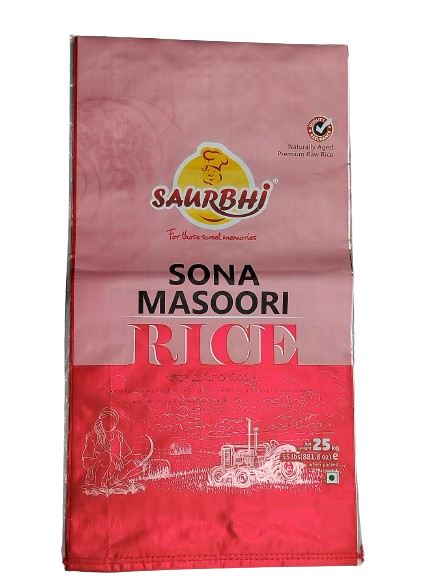

HDPE/PP WOVEN BAGS (LAMINATED/ UNLAMINATED)

HDPE/PP Woven Bags or Sacks with Huck-a-back weave and high anti-slip properties are considered some of the finest and durable packaging options. Commonly used for outdoor applications, these bags are ideal for storing grains and food materials. We offer 100% custom-designed polypropylene woven bags as per the desired specifications with specific UV requirements. Our range of laminated and unlaminated PP/HDPE woven bags and sacks are water-resistant, lightweight, yet strong enough to handle strains, providing a reliable packaging solution for various industries.

Single Colored Bags/Sacks (Laminated/Unlaminated)

Checks Designed Bags/ Sacks (Laminated/Unlaminated)

Multi-Color Strips (Laminated/Unlaminated)

Gusseted Bags/Sacks (Laminated/Unlaminated)

Top Hemmed Bags (Laminated/Unlaminated)

Flexo Printed Bags/Sacks (Laminated/Unlaminated)

Handle and D – Cut (Laminated/Unlaminated)

EZ Open Bags/Sacks (Laminated/Unlaminated)

Back Seam Bags/Sacks (Laminated/Unlaminated)

Technical Specifications

| Product | HDPE/PP WOVEN SACKS/ BAGS |

|---|---|

| Material | 100% virgin PP |

| Color | White, red, yellow or as per customer’s requirements |

| Printing | A. Coating & Plain bags: Max. 6 Colors B. BOPP film bags: Max. 8 Colors |

| Width | Circular Form – 30 cm to 70 cm (12” to 28”) |

| Length | As per customer’s requirements |

| Mesh | 10 X 10 Standard (8″ X 8″ to 14″ X 14” Inch) |

| Denier | 1000 Denier standard (400D- 1200D) |

| GSM | 35gsm – 110gsm |

| Top | Heat Cut, Cold cut, Zig-Zag cut or Hemmed |

| Bottom | Single fold and single stitched Double fold and single stitched Double fold and double stitched |

| Treatment | A. UV treated or as per customer’s requirements B. With gusset or as per customer’s requirements C. With PE liner or as per customer’s requirements |

| Surface Dealing | A. Coating or plain B. Printing or No printing C. 1/3 anti-slip, 1/5 anti-slip or as per customer’s requirements |

| Application | Packing rice, flour, wheat, grain, feed, fertilizer, potato, sugar, almond, sand, cement, seeds, etc. |

| Description | High tensile strength, falls and friction. Dimensional stability. A good surface for print tasks. UV-protection treatment if required. Food contact compliance |

| Packaging | 100pcs/bundle,500/1000pcs/bale or as customers’ requirements |

| MOQ | 10 tons |

| Production Capability | 700 Tons/Month |

| Delivery Time | The first container within 25 days after order confirmation, the later as per customer’s requirements |

| Payment Terms | T/T or L/C at sight |

| Certification | ISO 9001: 2015 |

Architect

Philip Larson

Venenatis faucibus. Nullam quis ante. Etiam sit amet orci eget eros faucibus im tincidunt. Duis leo. Sed fringilla mauris sit amet nibh. Donec sodales sagittis eo magna. Sed consequat, leo eget bibendum sodales, augue velit. Aliquam lorem.

Interior Designer

Jean Scott

Maecenas tempus, tellus eget condimentum rhoncus, sem quam semper libero, sit amet adipiscing sem neque sed ipsum. Nam quam nunc, blandit vel, luctus pulvinar, hendrerit id, lorem. Maecenas nec odio et ante. Cum sociis Theme done.

Account Manager

Brian Perry

Aliquam lorem ante, dapibus in, viverra quis, feugiat a, tellus. Sociis viverra nulla ut metus varius laoreet. Quisque rutrum. Aenean cum imperdi. Etiam ultricies nisi vel augue. Curabitur ullamcorper ultricies nisi. Nam eget. Maecenas necodio.

Engineering Manager

Alice Howard

Ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget rhoncus, amet sem vel quam nunc semper libero, sit amet sem neque sed ipsum. Namet quam nunc. Lorem ipsum sit.

Architect

Henry Sanchez

Aliquam lorem ante, dapibus in, viverra nisi quis, feugiat a, tellus. Phasellus viverra deo nulla ut metus varius qui laoreet. Quisque sum rutrum. Aenean imperdiet. Etiam ultricies cum sociis.

Engineering Manager

Nathan Marshall

Ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget rhoncus, amet sem vel quam nunc semper libero, sit amet sem neque sed ipsum. Namet quam nunc. Lorem ipsum sit.

construction simulator

Emma Romero

Aliquam lorem ante, dapibus in, viverra nisi quis, feugiat a, tellus. Phasellus viverra deo nulla ut metus varius qui laoreet. Quisque sum rutrum. Aenean imperdiet. Etiam ultricies cum sociis.

construction simulator

John Romero

Aliquam lorem ante, dapibus in, viverra nisi quis, feugiat a, tellus. Phasellus viverra deo nulla ut metus varius qui laoreet. Quisque sum rutrum. Aenean imperdiet. Etiam ultricies cum sociis.

Interior Designer

Judy Wells

Ultricies nisi. Nam eget dui. Etiam rhoncus. Maecenas tempus, tellus eget rhoncus, amet sem vel quam nunc semper libero, sit amet sem neque sed ipsum. Namet quam nunc. Lorem ipsum sit.